Which Material Cold Room Panel Is The Best: PU, PIR, or EPS?

When building a cold room, one of the key factors to consider is the insulation material for the panels. The insulation plays a crucial role in maintaining the desired temperature, energy efficiency, and overall performance of the cold room.

The three most common materials used for cold room panels are PU (Polyurethane), PIR (Polyisocyanurate), and EPS (Expanded Polystyrene). Each of these materials has unique properties that make them suitable for different types of cold storage environments.

In this article, we’ll take an in-depth look at each material to help you determine which one is best suited to your cold room requirements.

1. Polyurethane (PU) Panels

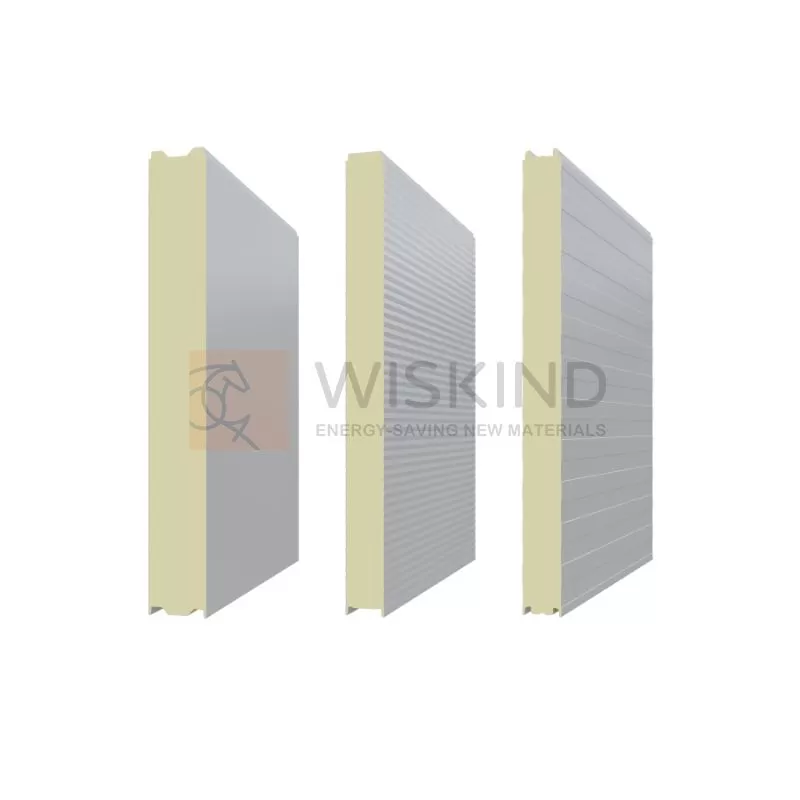

Polyurethane (PU) foam is renowned for its outstanding insulating properties, making it a popular choice in refrigeration and cold room construction. PU panels consist of a core of rigid polyurethane foam, sandwiched between two outer layers, often made from steel or aluminum.

PU Panel Advantages:

High Insulating Performance: PU panels offer exceptional thermal insulation, with low thermal conductivity. This ensures that the cold room maintains stable temperatures and operates more efficiently, reducing energy consumption.

Durability: PU is highly durable and resistant to moisture, making it ideal for cold storage environments. It can withstand prolonged exposure to low temperatures without degrading.

Long-Term Energy Efficiency: Thanks to its superior insulating properties, PU panels help to maintain consistent internal temperatures, contributing to long-term energy efficiency.

Lightweight: Compared to some other insulation materials, PU panels are relatively lightweight, which simplifies handling and installation.

PU Panel Disadvantages:

Cost: PU panels tend to be more expensive than materials like EPS, which may make them a less budget-friendly option for some projects.

Environmental Impact: The production of PU foam involves chemicals that can have a significant environmental impact, especially if the panels are not disposed of properly at the end of their life cycle.

2. Polyisocyanurate (PIR) Panels

Polyisocyanurate (PIR) panels are another popular choice for cold room insulation due to their impressive thermal insulation properties. PIR panels have a similar construction to PU panels, with a rigid foam core sandwiched between layers of steel or aluminum.

PIR Panel Advantages:

Superior Thermal Insulation: PIR panels have lower thermal conductivity than PU panels, making them highly effective at maintaining stable temperatures in cold rooms that require strict temperature control.

Fire Resistance: PIR panels offer superior fire resistance compared to PU. They are less flammable and can withstand higher temperatures, providing an added layer of safety in cold storage environments.

Energy Efficiency: Like PU, PIR panels provide excellent thermal insulation, which helps reduce the workload on refrigeration units, resulting in lower electricity costs and improved energy efficiency.

PIR Panel Disadvantages:

Higher Cost: PIR panels are generally more expensive than EPS panels, similar to PU, which may make them less cost-effective for some projects.

Brittleness: PIR panels are more brittle than PU panels, making them more prone to cracking or breaking under impact, which can be a concern during handling or installation.

3. Expanded Polystyrene (EPS) Panels

Expanded Polystyrene (EPS) is a commonly used insulation material composed of expanded polystyrene beads. It is widely utilized in cold room construction due to its affordability and reliable insulation properties.

EPS Panel Advantages:

Affordability: EPS panels are the most cost-effective option of the three. They are widely available and much cheaper than both PU and PIR, making them a budget-friendly choice for large cold room projects.

Good Insulation: While not as high-performing as PU or PIR, EPS still offers decent thermal insulation, making it suitable for cold rooms that don’t require extremely low temperatures.

Lightweight: EPS panels are lightweight, making them easier to handle and install, which can help reduce labor costs and construction time.

Moisture Resistance: EPS panels offer moderate resistance to moisture, though they are not as moisture-resistant as PU or PIR panels.

EPS Panel Disadvantages:

Lower Thermal Efficiency: EPS has a lower R-value compared to PU and PIR, meaning it is less effective at maintaining consistent temperatures in colder environments. Over time, this can lead to higher energy consumption.

Fire Risk: EPS is more flammable than PU and PIR, making it a less ideal choice in areas where fire resistance is important.

Durability: While EPS is moisture-resistant, it is more susceptible to physical damage than PU or PIR, and over time, it may degrade more quickly due to impact or wear.

Which Material Is the Best for Your Cold Room?

Choosing the right insulation material for your cold room depends on your specific requirements and priorities. Here’s a breakdown to help guide your decision:

For Superior Insulation and Energy Efficiency

If your priority is the best insulation, especially for very low-temperature environments, PU and PIR are the top choices. Both materials offer excellent thermal performance. PIR has the added benefit of higher fire resistance, making it a strong contender if both energy efficiency and safety are crucial.For Budget-Conscious Projects

If keeping costs low is a major concern and your cold room doesn’t require extremely low temperatures, EPS is the most cost-effective option. It provides adequate insulation at a fraction of the cost of PU and PIR, making it ideal for budget-conscious projects that still require reliable performance.For Fire Safety and High-Performance Cold Rooms

PIR is the best material if fire resistance is a top priority. It combines high thermal insulation with superior fire resistance, making it particularly suitable for cold rooms where safety and long-term performance are essential.